Glossy Soot in the Chimney – Underestimated, but Relevant

What is Meant by ‘Glossy Soot’

Glossy soot in the chimney is not simply ‘a little soot’. It usually refers to dark, tar-like deposits that tend to be shiny, hard or greasy to the touch and prefer to form where flue gases cool down – for example, in the flue pipe, at the stove connection or in the chimney. Unlike dry soot, shiny soot often cannot simply be brushed off: it adheres more strongly and can build up in layers.

Why Shiny Soot is More Than Just a Cleaning Problem

Shiny soot is particularly relevant because it is flammable. If large quantities accumulate, the risk of a chimney fire can increase. At the same time, shiny soot is often an indication that combustion is not running optimally. Typical accompanying symptoms include, for example:

- the stove ‘draws’ less efficiently or reacts sluggishly to air regulators

- the window becomes sooty more quickly than usual

- a noticeable amount of deposits form in a short period of time

- the combustion appears ‘dark’ and uneven rather than clear and hot

This means that anyone who discovers shiny soot should not only think about removing it, but also about the cause. Even after cleaning, shiny soot can quickly return if the heating conditions remain the same.

What You Will Learn in This Article

In this article, you will learn what causes shiny soot, why it can be dangerous and how much shiny soot is normal – in other words, when it is just a light deposit and when action needs to be taken. We will also show you how to remove shiny soot safely (without risky experiments) and how you can prevent it in the long term by optimising combustion. In addition, we will explain how measures such as stove fine dust filters can fit into clean, low-emission heating behaviour.

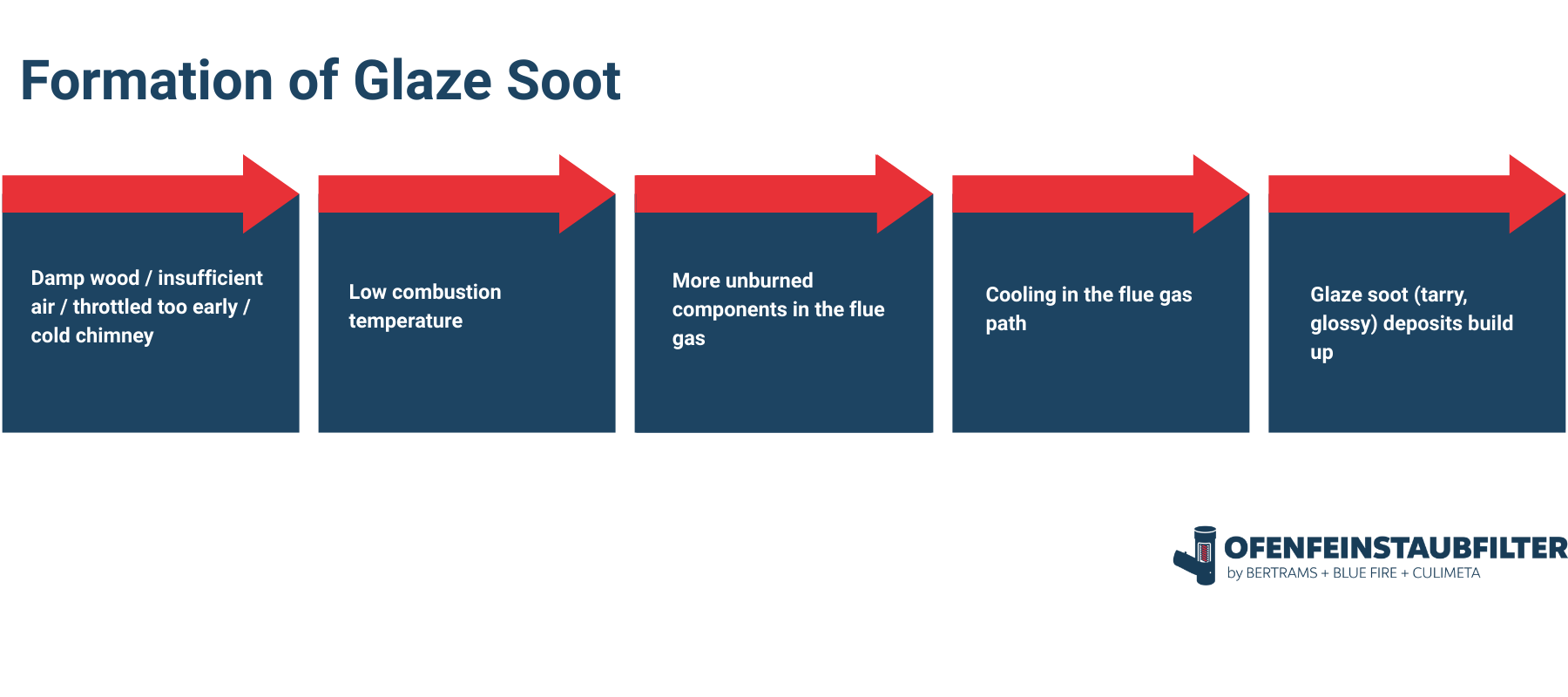

How Shiny Soot is Formed – Causes in Combustion

The Main Reason – Too Cold, Too Little Air, Too Much ‘Smouldering’

Shiny soot usually forms when wood does not burn cleanly and is not hot enough. Instead of a stable, bright flame, the combustion tends to be low in oxygen and ‘smouldering’: more unburned components are produced in the flue gas, which later settle as a tar-like layer in cooler areas. This is particularly favoured when the stove runs at partial load for a long time or the air supply is severely restricted so that a load of wood ‘lasts as long as possible’.

Typical situations that promote glossy soot:

- You restrict the air early on, even though the fire is not yet really hot.

- The wood smoulders for a long time instead of burning actively. (too little combustion air)

- The stove often runs in ‘economy mode’ with small flames.

Fuel – Wood That Is Too Damp and Unsuitable Materials

A very common trigger is firewood that is too damp. Moisture costs combustion energy: a large part of the heat is ‘used’ to evaporate water. This lowers the temperature in the combustion chamber – and this is precisely what increases the likelihood of deposits in the flue gas path.

Also, make sure you only use suitable fuels. Treated wood, painted residues, chipboard or waste can not only cause more deposits, but also release harmful emissions and put strain on the system.

Avoid burning wood that contains resin, such as pine or spruce. If softwoods are used as firewood, they should always be mixed with hardwoods, such as beech.

Practical check for wood:

- Effective:

- Wood with low residual moisture (as a rule of thumb: well dried and correctly stored)

- The residual moisture should always be less than 20%. A lower residual moisture content would be even more advantageous.

- Critical:

- Wood that hisses when lit, smokes heavily or does not burn steadily

Common Operating Errors With Stoves (often unnoticed)

Glossy soot often has less to do with the stove model and more to do with recurring heating habits. It often starts with too little air being supplied at the beginning: the fire does not really get going, the temperature remains too low and combustion is not clean. It is similarly critical if the air supply is throttled too early – i.e. before a stable flame pattern and a hot bed of embers have developed. Even a very small ‘mini-fire’ can be problematic because, especially when the chimney is still cold, it often does not generate enough heat and therefore cannot build up sufficient negative pressure in the chimney. Leaving the fire to smoulder for a long time, for example overnight, is also particularly conducive to the formation of glossy soot. This produces many tar-like components that can then settle in the flue.

If you want to avoid these typical routines, here are some practical tips for everyday life: Heating correctly: 10 professional tips for clean combustion.

Chimney & Draught – When Flue Gases Cool Down too Quickly

The conditions in the flue gas path also influence whether shiny soot forms. If the chimney is still cold or the negative pressure is too low, the flue gases cool down more quickly – and this is exactly when tar-like components can settle more easily on the inner walls. This happens, for example, when combustion times are very short and the chimney does not reach the right temperature and therefore does not build up enough negative pressure. This can easily occur, especially in the cool transition period when condensation in the flue is favoured, or in unfavourable weather conditions such as certain wind and pressure conditions. It is important to note that this does not automatically mean that ‘the chimney is to blame’. It explains why shiny soot forms more quickly in some systems, even though their use is subjectively perceived as ‘completely normal’.

Quick Test – Identify the Cause in 60 Seconds

If you suspect shiny soot, these questions will help you make an initial assessment:

- How does your fire usually burn? More flame – or more embers?

- How quickly do you restrict the air? Only after a stable flame/embers – or early on?

- What is your wood like? Stored in a dry place – or rather damp, with residual moisture above 20%?

- How often do you heat in partial load mode? Frequent long, weak burns?

If you find yourself nodding in agreement to several of these points, it is highly likely that glossy soot is being caused primarily by combustion temperatures that are too low and insufficient air supply.

How much Shiny Soot is Normal? Realistic Classification & Warning Signs

Shiny Soot vs. Normal Soot – The Quick Distinction

A light, dry film of soot can occur in wood-burning stoves – especially during the heating phase. Shiny soot, on the other hand, is usually tarry, has a shiny/varnish-like appearance and adheres much more strongly. As a rule of thumb, anything that shines, smears or feels like a hard, tarry layer is not ‘normal’ but an indication of unfavourable combustion conditions or severe cooling of the flue gases.

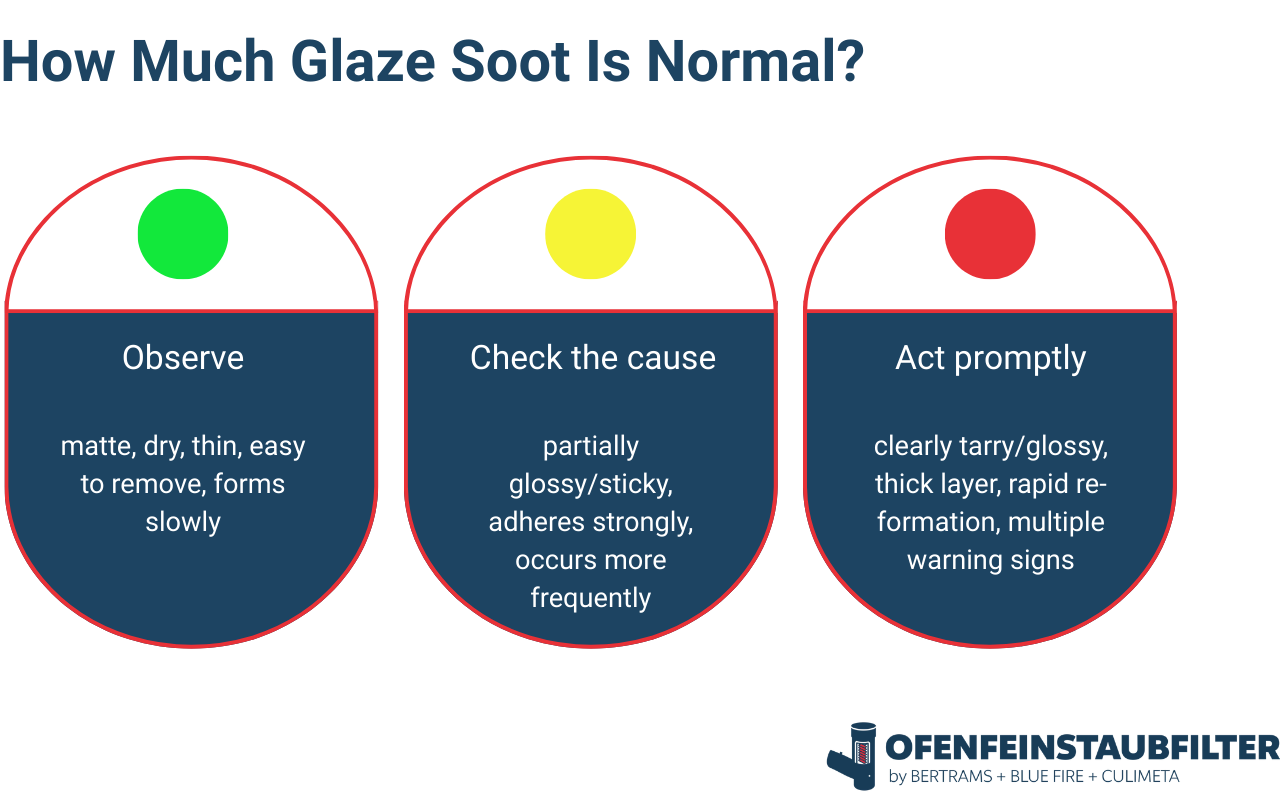

How Much Shiny Soot Is Normal? Classification According to Appearance, Feel and Frequency

It is difficult to specify exact quantities in everyday use because many factors play a role (wood, air, temperature, draught). A simple classification is helpful in practice:

- Rather uncritical (observe):

- Thin, matt, dry, easily removable, does not reappear quickly.

- Noticeable (check cause):

- Shiny or sticky in places, sticks strongly, becomes visibly more.

- Critical (take prompt action):

- Clearly shiny/tarry, thicker layers, large areas or rapid reformation despite ‘correct’ heating.

If you are unsure, the following applies: As soon as it shines and sticks, do not wait.

Warning Signs During Operation – When Action Is Needed

Glanzruß often appears during the operation of the stove. Typical signs include a window that quickly becomes covered in soot, noticeably poor draught, increased smoke development, a strong/pungent odour or a conspicuous amount of deposits in a short period of time (e.g. on the flue pipe/stove connection). Action should be taken at the latest when deposits are shiny/tarry, visibly build up, reappear quickly or several warning signs occur simultaneously.

Why Soot Can be Dangerous

Chimney Fire – the Greatest Risk with Soot

First things first: glossy soot is flammable. When tar-like deposits build up in the flue pipe or chimney, they can ignite under certain conditions. The risk increases especially when the layer becomes thicker or when very high temperatures are reached during heating (e.g. after prolonged smouldering phases followed by a ‘full throttle’ phase). A chimney fire is not only loud and frightening, but can also put a heavy strain on the system and, in the worst case, cause damage to the chimney, adjacent components or even a building fire.

Important: Not every deposit automatically leads to a chimney fire. But glossy soot is exactly the type of deposit where the risk should be taken seriously – because, compared to dry soot, it can be more energy-rich and more flammable.

Consequences in Everyday Life – Poor Draught, More Smoke, More Deposits

Even without an acute emergency, shiny soot can noticeably impair operation. Deposits narrow the exhaust gas path, alter the flow and can have a negative effect on the chimney draught. This often manifests itself as follows:

- The stove starts less easily and takes longer to burn steadily.

- When adding more fuel, more smoke is produced or the smoke is ‘sluggish’.

- The window gets sooty more quickly, even though you are actually heating ‘normally’.

- Overall, new deposits form more quickly – a self-reinforcing cycle.

In short: shiny soot is often not just a symptom, but can worsen conditions to such an extent that even more shiny soot is produced.

Why Shiny Soot Can Also Affect Emissions and Efficiency

Glossy soot is usually an indication of combustion that is not running optimally. This often means more unburned components in the flue gas, more particles, more odour – and less usable heat from the wood. At the same time, there is an increased likelihood of condensates and tar-like substances settling in the exhaust gas path, which increases maintenance costs and risk.

This is precisely why the best strategy is not only to ‘remove glossy soot’, but also to improve combustion and operate the system in such a way that deposits do not form in the first place. The next chapter therefore deals specifically with how to safely remove glossy soot (and which methods are best avoided) – and how to prevent it in the long term by optimising combustion and taking sensible measures.

Safely Remove Glossy Soot – and Prevent It Permanently

Safety First: What You Should Not Risk When Dealing with Glossy Soot

If you suspect glossy soot in your fireplace or chimney, the most important rule is: do not experiment. Attempts to ‘burn off’ deposits or deliberately heat the stove to extremely high temperatures in order to get rid of shiny soot are particularly risky. In the worst case, this can cause the deposits to ignite. Aggressive household remedies or unsuitable tools can also damage components or loosen deposits in an unfavourable way.

If deposits appear shiny, tarry or hard, or build up quickly, a professional assessment (e.g. during regular inspection/cleaning) is the safest way to correctly assess the risk.

Removing Shiny Soot: This Is How to Proceed Safely

The exact removal process depends on where the shiny soot is located and how pronounced it is. As a general rule, the thicker and more tarry the layer, the more likely it is that removal should be left to experts.

What you can do yourself safely without taking any risks:

- Optimise operation immediately: do not allow the fire to continue to smoulder, do not throttle it early, use dry wood (details in 5.3).

- Observe accessible areas: e.g. only check the flue pipe/stove connection where it is intended by the manufacturer and can be safely accessed.

- Clean regularly: so that deposits do not grow unnoticed.

When professional assistance from a chimney sweep is advisable:

- if shiny soot is clearly visible or recurring

- if deposits are hard/tarry and cannot be removed normally

- if the stove has poor draught, smokes unusually or smells of ‘tar/smoke’

- if there is uncertainty as to whether it is normal soot or shiny soot

This ensures that ‘removing shiny soot’ is not just a superficial task, but is done safely and appropriately for the situation.

Prevention Through Combustion Optimisation: The Most Important Adjustment Screws

The best strategy against shiny soot is to prevent it from forming in the first place – and this can often be achieved with just a few adjustments in daily practice. The most important thing is to use suitable, well-stored and sufficiently dry wood, because damp firewood lowers the combustion temperature, produces more smoke and promotes tar-like deposits. A hot, clean start is just as important: provide sufficient air at the beginning and ensure a stable flame so that the exhaust gas path heats up quickly. You should only throttle the air supply once a hot bed of embers has formed and the flames are burning calmly and steadily – reducing the air supply too early is one of the most common causes of shiny soot. You should also consistently avoid smouldering, i.e. leaving the fire to glow for a long time, very small fires or burning overnight, as this produces a particularly large amount of tarry components. Regular maintenance also helps: if the seals and airways are intact and the exhaust gas path remains clean, this supports a stable draught and reduces the risk of glossy soot forming again.

The Role That Stove Fine Dust Filters Can Play

Stove fine dust filters are primarily designed to reduce particle emissions. They are no substitute for clean combustion – but they can be part of an overall concept: if you want to optimise combustion (dry wood, sufficient temperature, correct air flow) and also reduce emissions, you can retrofit a suitable fine dust filter. The order is important: first optimise combustion, then make sensible use of technical additions. In this way, both measures support each other, instead of a filter having to compensate for ‘problems from the combustion chamber’.

If you want to further reduce your emissions and operate your stove more cleanly in the long term, you will find all the information you need about suitable solutions and retrofitting on our website – discover stove fine dust filters and select the right solution.

FAQ: Frequently Asked Questions About Soot Deposits in Fireplaces

Can I remove the soot deposits myself or is professional cleaning necessary?

That depends primarily on how thick the deposits are and where they are located. Light, dry soot deposits in accessible areas can often be removed as part of normal stove maintenance. However, you should not attempt to remove shiny, tarry or hard layers yourself – especially not using risky methods such as deliberately burning them off or heating the stove to extremely high temperatures. If shiny soot is clearly visible, returns quickly or the stove’s draught noticeably deteriorates, it is advisable to seek professional advice. This will ensure that the soot is removed safely and the cause is investigated at the same time. In such cases, be sure to consult your chimney sweep.

How much shiny soot is normal – and when should I take action?

As a rough rule of thumb, shiny soot is not normal. A thin, dry film of soot may occur, especially during the heating phase. However, if deposits are shiny, greasy or feel like a tar-like layer, you should not wait. At the latest when the deposits build up visibly, recur quickly or warning signs occur at the same time (e.g. windows becoming sooty more quickly, poor draught, more smoke), it makes sense to take action – either through consistent combustion optimisation and/or professional inspection.

Does a fine dust filter help against shiny soot – or only against fine dust?

A fine dust filter is primarily designed to reduce particle emissions. It does not directly help against the formation of shiny soot, because shiny soot is mainly caused by unfavourable combustion and cooling of the flue gases. Nevertheless, a filter can be part of a sensible overall concept: if you want to optimise combustion (dry wood, sufficient air, no smouldering) and also reduce emissions, a suitable filter solution can complement the system. The key is to first eliminate the cause and then take targeted technical measures.